Plant growth is determined by five factors: heat, water, nutrients, light, and carbon dioxide. An insufficient amount of any one of these can seriously debilitate your crop.

In an indoor environment, heat, water, and nutrients never pose any problem to the cultivator: ample supplies of each are readily available. Light is provided by using natural light and/or a variety of artificial sources (see Chapter 10). This leaves carbon dioxide (CO2).

CO2 is a gas that makes up about .03 percent (300 parts per million, or “ppm”) of the atmosphere. It is not dangerous. It is one of the basic raw materials (water is the other) used by plants in the act of photosynthesis. And it can make those little buggers grow like crazy.

When plants are growing in an enclosed area, there is a limited amount of CO2 for them to use. When this CO2 is used up, the plant’s photosynthesis stops. Only as more CO2 is provided can it use light to continue the process. Adequate amounts of CO2 may be easily replaced in well-ventilated areas. However, a more-than-adequate amount — .2 percent (2000 ppm), or six times the amount usually found in the atmosphere — can increase the growth rate by up to a factor of five. For this reason, many commercial nurseries provide CO2 enriched air for their plants.

The two most economical and convenient ways to give your plants all the CO2 they’ll ever need are: (1) use a CO2 generator that burns natural gas or kerosene, and (2) use a CO2 tank with a regulator.

First, of course, you must find out how much CO2 is needed to bring the growing area up to the ideal level of 2000 ppm. To do this, multiply the volume of the growing area (length x height x width) by .002. The result represents the number of cubic feet of gas required to reach optimum CO2 range. For instance, a room that measure 13’ x 18’ x 12’ contains 2,808 cubic feet; 2,808 x .002 equals 5.6 cubic feet.

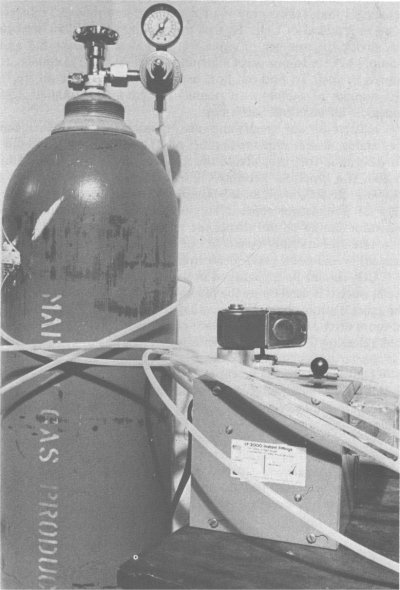

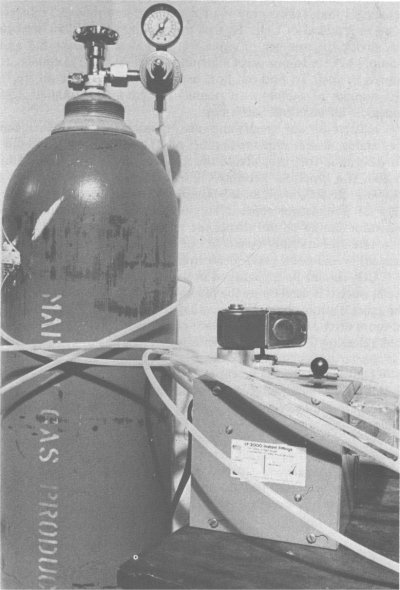

The easiest way to supply the gas is to use a CO2 tank. All the equipment you’ll need can be obtained from a welding supply store. The tank, which comes in 20-and 50-pound sizes, can be bought or rented. (A 50-gallon tank, filled, has a gross weight of 170 pounds.) To regulate dispersal of the gas, a “combination flow meter regulator” is required. It regulates the flow to between 10 and 50 cubic feet per hour. A solenoid valve turns the flow meter on and off. This can be operated manually, or by a 24-hour timer. The timer should be a multicycle one, so that the valve can be turned on and off several times each day. If the growing room is small, a short-range timer is needed. Most timers are calibrated in ½-hour increments, but a short-range timer can keep the valve open for just a few minutes if necessary.

To find out how long the valve should remain open, divide the number of cubic feet of gas required (in our example, 5.6 cubic feet) by the flow rate. For instance, if the flow rate is 10 cubic feet per hour, 5.6 divided by 10 equals .56 hours, or 33.6 minutes (.56 x 60 minutes 33.6). At 30 cubic feet per hour, on the other hand, the number of minutes would be 5.6 divided by 30, then multiplied by 60, or 11.2 minutes.

Be sure to place the tank in an area where it can be replaced easily. Run a hose from the top of the tank unit to the top of the garden. CO2 is cooler and heavier than air and will flow downward, reaching the tops of the plants first.

Gas and kerosene generators work by burning hydrocarbons that release heat and create carbon dioxide and water. Each pound of fuel burned produces about 3 pounds of CO2, 1½ pounds of water, and about 21,800 BTUs (British Thermal Units) of heat.

Nursery supply houses sell CO2 generators specially designed for greenhouses, but household-style kerosene or gas heaters are also suitable. This apparatus needs no vent. The CO2 goes directly into the room’s atmosphere. A good heater will burn cleanly and completely, leaving no residues, creating no carbon monoxide, If a heater is not working correctly, most likely it will burn the fuel incompletely and create an odor. More expensive units have pilots and timers; less expensive models must be adjusted manually. Heaters with pilots can be modified by using the solenoid valve and timer.

At room temperature, one pound of CO2 equals 8.7 cubic feet. Remember that it takes only 1/3 of a pound of kerosene (5.3 ounces) to make a pound of CO2. To find the amount of fuel you need to use, divide the number of cubic feet of gas required by 8.7 and multiply by .33. In our case, 5.6 cubic feet ÷ 8.7 x .33 equals .21 pounds of fuel. To find out how many ounces, multiply .21 by 16 (the number of ounces in a pound) to arrive at a total of 3.36 ounces, a bit less than half a cup.

Heaters do not specify the rate at which they burn fuel, but they almost always state the number of BTUs produced in an hour. To determine fuel use, divide the number of BTUs produced by 21,800. If a generator produces 12,000 BTUs per hour, it is using 12,000 ÷ 21,800, or about .55 pounds, of fuel per hour. However, only .21 pounds are needed. To find the number of minutes the generator should be on, divide the amount of fuel needed by the flow rate and multiply by 60. In our case, .21 (the amount of fuel needed) ± .55 (flow rate) x 60 equals 22.9 minutes.

CO2 should be replenished every three hours during the light cycle, since it is used up by the plants and leaks from the room into the general atmosphere. Well-ventilated rooms should be replenished more often. It is probably more effective to have a generator or tank releasing CO2 for longer periods of time, at slower rates, than for shorter periods at higher rates.

The simple process of supplying plants with CO2 can increase the yield of any indoor garden considerably, so plan on decreasing the turnaround cycle of your garden — or raising the height of the ceiling.