Chapter Eleven

Four Ways to a Better Grow Room

I know a person with a very observant eye and a keen sense of the possible. One day we were walking through a commercial area where men were unloading boxes from a truck. ‘Fred’ asked to see the manager, and told him that he could improve the effi- ciency of the operation by 30 percent if he was paid $100. The manager agreed to pay if it worked. Fred showed the manager that the men were loading only two boxes on each truck, while, if the boxes were loaded sideways, the trucks could hold four. The man- ager reluctantly wrote a check.

On the way out, Fred said, “I can still cut unloading time by 30 percent for $50.” The manager shook his head, but as we began to leave he called us back and agreed. Fred told him to increase the length of the platform on the hand trucks by attaching a board to them. The manager handed Fred a President Grant, shaking his head with an ‘I should have known’ look. A study of any operation will reveal many areas for improve- ment. Even seasoned experts can overlook fundamental principles. For example, take two gardens, “A” and “B”, maintained by experienced cultivators:

On the way out, Fred said, “I can still cut unloading time by 30 percent for $50.” The manager shook his head, but as we began to leave he called us back and agreed. Fred told him to increase the length of the platform on the hand trucks by attaching a board to them. The manager handed Fred a President Grant, shaking his head with an ‘I should have known’ look. A study of any operation will reveal many areas for improve- ment. Even seasoned experts can overlook fundamental principles. For example, take two gardens, “A” and “B”, maintained by experienced cultivators:

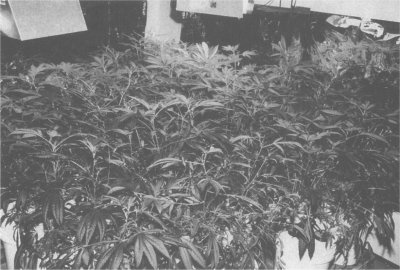

Garden A is lit by two vertical 1000-watt metal halide (MH) lamps with wide reflectors on a rotating light mover. There is an aisle between the wall and the garden. The plants grow in 3-inch cups filled with expanded clay, placed in 9-inch tubes. They are irrigated by two constant-flow sprayers aimed at each cup.