State-of-the-Art CO2 Injection and

Environmental Controls

Recently several

manufacturers have introduced equipment that allows extremely fine

control over most of the environmental factors in the high-tech indoor

growing environment. These systems that automatically monitor the

temperature and humidity, and turn on the exhaust fan or an airconditioner or dehumidifier any time the temperature or humidity rises

above pre-set levels.

After the exhaust cycle is completed, the fan stops and the necessary amount of CO2 is injected into the air. The injection is facilitated by a small timer that opens the solenoid valve and releases CO2 for a predetermined number of seconds.

The equipment remains off until one of three things happens:

- the temperature rises above the predetermined limit,

- the humidity rises above the predetermined limit or,

- the amount of time set on the main clock transpires and another cycle is initiated.

Periodic CO2 Injection

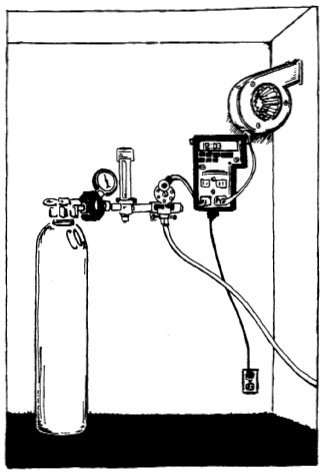

The CO2 injection system pictured on

page 24 contains an integrated fan system. The fan is necessary to remove

the stale air

and replace it with clean, fresh air from outside before

additional CO2 is injected into the room. Here is how the system

works:

- The clock timer cycles every hour, causing the mechanism to turn a switch on or off on a minute by minute basis. The clock timer is usually set to turn on the exhaust fan for a certain number of minutes once, twice, or three times an hour.

- After the fans have exhausted the air in the room and replaced it with fresh air from the outside, CO2 is injected into the air in adequate amounts to bring the CO2 levels up to optimum. The CO2 timer determines the amount of time that the CO2 release valve remains open, usually measured in seconds.

- The regulator shows the pressure of gas in the tank and the cubic feet per minute at which the gas is being released when the solenoid valve is opened.

Evacuation! Injection

Cycles

There are a number of reasons that growers choose different

lengths of time between cycles for the evacuation/injection process. The

exhaust fan does a lot more than just change the air to eliminate CO2

depletion. Artificial lighting often causes a heat build-up. Periodically

replacing the hot, stale air with cool, fresh air helps keep the heat

within acceptable limits. Also, plants transpire water through their

leaves into the air during the growth process. This raises the humidity,

which can also make the environment prone to mold and rot, as well as

cause loose, stringy plant growth.

Depending on the location, season,

placement of the chamber in the house, and other factors, the temperature

and humidity changes from day to day. In many cases, simply changing the

air and re-injecting CO2 can cure a problem with temperature or humidity

build-up. This is because the heat and moisture-laden air that builds up

in the room is replaced with cool, fresh, drier air from the outside.

Seasonal changes in the weather often result in alterations

to the time between evacuation/injection cycles. For example, as the

temperature heats up in the summer, more frequent cycles are necessary

because the air being drawn into the chamber is considerably warmer to

begin with, and therefore rises more quickly to the point where the

temperature is unduly high. In some locales, more cycles may be warranted

in the winter rainy season, because the air being drawn into the room

contains more moisture.

Tubing and CO2

Dispersion

CO2 must be

introduced into the grow room in the proper manner for it to do its job

correctly. Some equipment manufacturers recommend a perforated tube

strung around the ceiling with small holes to let the cool CO2 fall down

over the plants. This is a must in a grow room with inadequate internal

circulation, but the CO2 probably won’t do much in these circumstances.

It quickly falls to the floor and escapes through cracks in the baseboards

in a room with improper internal circulation.

Large, heavy duty, oscillating fans are

the solution. You just can’t get too much air blowing around in the

growth chamber, both above and below the green canopy. (See drawing.)

CO2 Tanks

A CO2 tank can be a monster. Even

the little ones can be little monsters! Why? Because they weigh far more

than most people estimate.., especially half way up a few flights of

stairs.

The smaller tanks are referred to as twenty pound CO2

cylinders. That is because they hold 20 pounds of CO2 gas. But don’t let

the nomenclature fool you. A twenty pound steel tank weighs about 50

pounds when full. A full fifty pound tank weighs about 170 pounds.

Tanks are

available for sale or rental at welding supply companies. This is where a

tank is re-filled. (Usually the empty tank is swapped for a full one.)

CO2 tanks are regularly used by welders, bars, and people

with home beer tappers.

Always protect the valve from being knocked off or damaged

in an industrial accident. Always chain the tank to the wall in an upright

position to prevent accidental tip-over.

Regulator Freeze -

Up

Gas is extremely cold when it

escapes from the tank. A quick blast can do damage to skin tissue or eyes.

Be careful!

CO2 can also freeze and ruin a regulator. In haste to supply

CO2 to the waiting plants, many growers crank the regulator up to a

flow-rate that can cause cause regulator freeze-up. This can occur at

anything above 20 CFH (cubic feet per hour). Special heated regulators are

available for those with a large area, or a shortage of

patience.

Determining CO2 Release

Time

At 20 CFH, each minute of CO2 release yields one-third of a

cubic foot of CO2 released. A 10 X 10 X 8 foot room would require a little

over 3 minutes of CO2 release.

Advantages of Injection

- Periodic injection of CO2 is very clean.

- Precise control of CO2 levels is easy.

- Injection does not add to temperature or humidity.

- When injected into a powerful fan or through a perforated tube suspended from the ceiling, the CO2 is easily dispersed throughout entire growing area.

- There is no danger from flame, heat or flammable gas.

Disadvantages of Injection

- An injection system requires handling of heavy tanks which must be taken in and out of growing area on a regular basis for refilling.

- The cost is high for the initial equipment, then very low for the CO2 itself (compared to other methods).

- A very slight danger is present from valve damage causing the tank to become an uncontrolled projectile powered by gas escaping at up 1000 pounds per square inch of pressure.

- Another slight danger (although probably more likely to happen than the previous scenario) is the displacement of air that can happen in the event of quick release of all the CO2 in a tank into a closed area. Both plant and human can perish in this event. Not because CO2 is a poisonous gas, but because the CO2 can displace all the oxygen in the area, causing asphyxiation, or death from lack of oxygen.

The author of this book was nearly asphyxiated while running

a machine that was activated by CO2 release, causing a slow but steady

build-up of CO2 in the room, gradually displacing all the oxygen.

Asphyxiation symptoms come on slowly. They begin with a

sleepy and lethargic feeling, and can be followed by a desire to lay down

for a nap. There are no ”danger sign” feelings in the lungs. If you feel

this way when in your growing chamber, get out quickly! Check your

equipment for signs of malfunction

later.