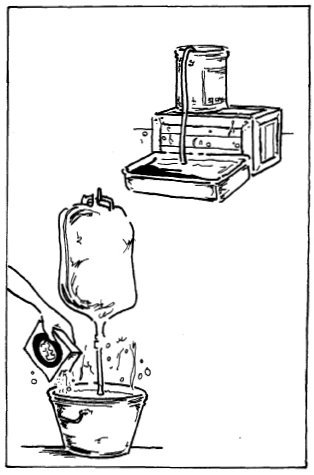

Generation of CO2 in

the grow room by dripping vinegar (acetic acid) into a bed of baking soda

is a recent development in the world of indoor gardens. (See drawing.)

This method is best suited for a small closet type operation. There is no

temperature rise, no water vapor is created, and there is no risk of fire.

Although the equipment to generate CO2 chemically is inexpensive, the cost

of the vinegar and baking soda makes this an expensive method.

Compared to timed cycles of exhaust followed by injection, the continuous drip soda/acid method lags far behind injection in its capacity to produce and maintain the optimum levels of CO2 for best growth. This is due to its process of continuous but slow release of CO2.

Assuming that

we are working with a grow area with a timed exhaust cycle, the gas

generated from the continuous drip soda/acid method would start out at

just above the 300 ppm available in the air drawn into the growth chamber

from outside. As the vinegar drips into the soda, CO2 is continuously

formed and the CO2 level in the room rises. It usually takes a

considerable portion of the cycle for the CO2 to build to the point where

it does much good. If the CO2 is generated too rapidly, it can reach

levels where it is detrimental and even toxic to the plants.

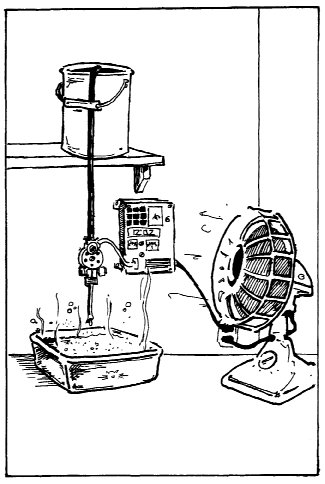

Cyclic Vinegar Dump Device

The accompanying illustration shows

a design for a CO2 device that periodically drops an easily regulated

amount of vinegar into a bed of soda. The solenoid operated dump valve

dispenses the vinegar into the soda after completion of the periodic

exhaust cycle. The CO2 generation is safe, rapid, and similar in many

aspects to release of CO2 from a timed injection system.

This system is unavailable

commercially, and I have not tried the design, but construction and

operation should be straightforward.

It is important to find a timer that

permits settings of at least one opening per hour, and will dispense the

vinegar without any pressure.

There are a lot of complex formulas

that can be used to determine how much of what to add how often. The best

bet is to make a rough guess, and then set the system up in the manner in

which it will be operated. Be prepared to take a number of tests with the

glass tube/ syringe CO2 tester. Take the test after the first vinegar

dump, and then adjust the burette or IV bottle by increasing or

decreasing the rate at which it fills to a point where it will contain

more or less vinegar when the next exhaust! vinegar dump cycle

occurs.

The variables in this piece of

equipment (dump cycle and fill rate) are easily controlled. The settings

that produce 1500 ppm one time should do the job pretty much the same way

every time.